Key Takeaways

- CNC plasma cutting machines use computer-guided plasma torches to cut conductive metals quickly and precisely, revolutionizing metal fabrication processes.

- These machines are available in table and portable models, allowing flexibility for industrial manufacturing, on-site construction, and custom projects.

- Key advantages include high-speed cutting (up to 500 inches per minute), exceptional precision, versatility across metal types and thicknesses, and reduced labor costs.

- CNC plasma cutting supports a wide range of industries, including automotive, aerospace, construction, and art, enabling the production of both intricate and large-scale components.

- Choosing the right CNC plasma cutter depends on factors such as production volume, required precision, workpiece size, and intended application.

CNC plasma cutting machines use computer-guided plasma torches to cut conductive metals quickly and precisely, revolutionizing metal fabrication with temperatures exceeding 20,000°C and cutting speeds up to 500 inches per minute. Available in table and portable models, these machines offer high-speed cutting, exceptional precision with tolerances as tight as ±0.01 inches, versatility across metal types and thicknesses, and reduced labor costs through automation. They support diverse industries including automotive, aerospace, construction, and art, enabling production of both intricate and large-scale components. For comprehensive precision manufacturing solutions including advanced CNC capabilities, CNC Machining Services from Yijin Hardware provide CNC machining, sheet metal fabrication, die casting, injection molding, and 3D printing services, delivering tailored, high-quality solutions across automotive, aerospace, medical, and energy sectors with integrated manufacturing workflows.

What Is a CNC Plasma Cutting Machine

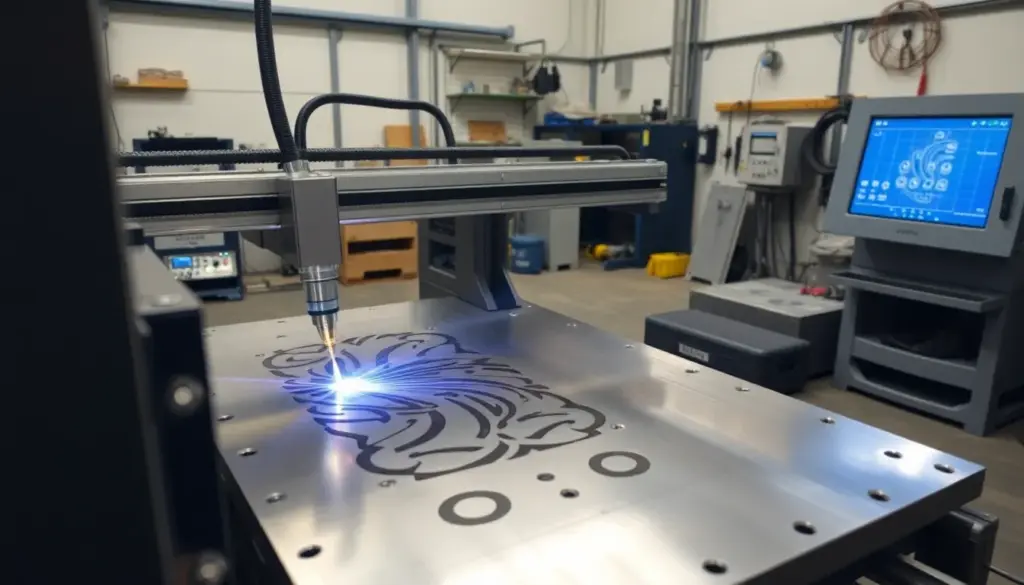

A CNC plasma cutting machine uses computer numerical control to guide a high-velocity jet of ionized gas—plasma—to cut conductive metals. Operators input designs into the system, then the computer directs the plasma torch with precision across materials like steel, aluminum, or copper. Machines use a power supply to generate plasma at temperatures above 20,000°C, melting through metal up to 2 inches thick in industrial applications.

Shops employ CNC plasma cutting for intricate, repeatable shapes. Fabricators use these machines for signage, automotive parts, structural frames, and custom components. Automated control produces consistent accuracy, with tolerances as tight as ±0.01 inches in advanced systems.

Yijin Hardware in Homestead, FL integrates CNC plasma cutting into its manufacturing lineup for fast prototyping and production runs. Gavin Yi, CEO, maintains that combining CNC plasma with in-house CNC machining and sheet metal fabrication expands capabilities. Customers in automotive, aerospace, medical, and energy sectors rely on Yijin Hardware’s equipment to maintain tight part specifications and efficient workflows. Machine setups minimize manual intervention, reducing the time from design to finished product.

How CNC Plasma Cutting Machines Work

CNC plasma cutting machines use computer control and a high-temperature plasma jet to cut metal with precision. They rely on coordinated hardware and a programmed cutting process to achieve consistent results.

Components and Technology

Core components include the CNC unit, plasma torch, power supply, gas delivery, and cutting table. The CNC unit interprets operator input and G-code instructions for path accuracy. The plasma torch, holding both the electrode and nozzle, starts the arc using either a high-frequency spark system or a moving-contact start-pilot arc system. The power supply generates the required arc voltage. Compressed air or inert gas flows through the nozzle, forming a high-velocity plasma stream exceeding 20,000°C. A water or downdraft cutting table supports the metal workpiece and reduces fumes or warping. The system integrates input devices for program loading and manages plasma on/off timing along with movement control.

The Plasma Cutting Process

The cutting sequence begins when operators transmit a part program to the control system. The CNC activates the power supply, ionizing the gas that forms the plasma arc. The torch, guided by the CNC, melts the workpiece along the programmed path. The plasma jet melts the metal cleanly while the pressurized gas blows away molten material, producing a sharp edge. The CNC regulates the torch motion and speed to ensure consistent, accurate cuts on metals such as steel, aluminum, brass, and copper. A water or downdraft table captures debris and minimizes thermal distortion. The automated process ensures high repeatability, supporting detailed part production in manufacturing and fabrication settings.

Types of CNC Plasma Cutting Machines

CNC plasma cutting machines appear in two main configurations: table models and portable units. Each type matches specific metal fabrication needs, with unique advantages for different manufacturing environments.

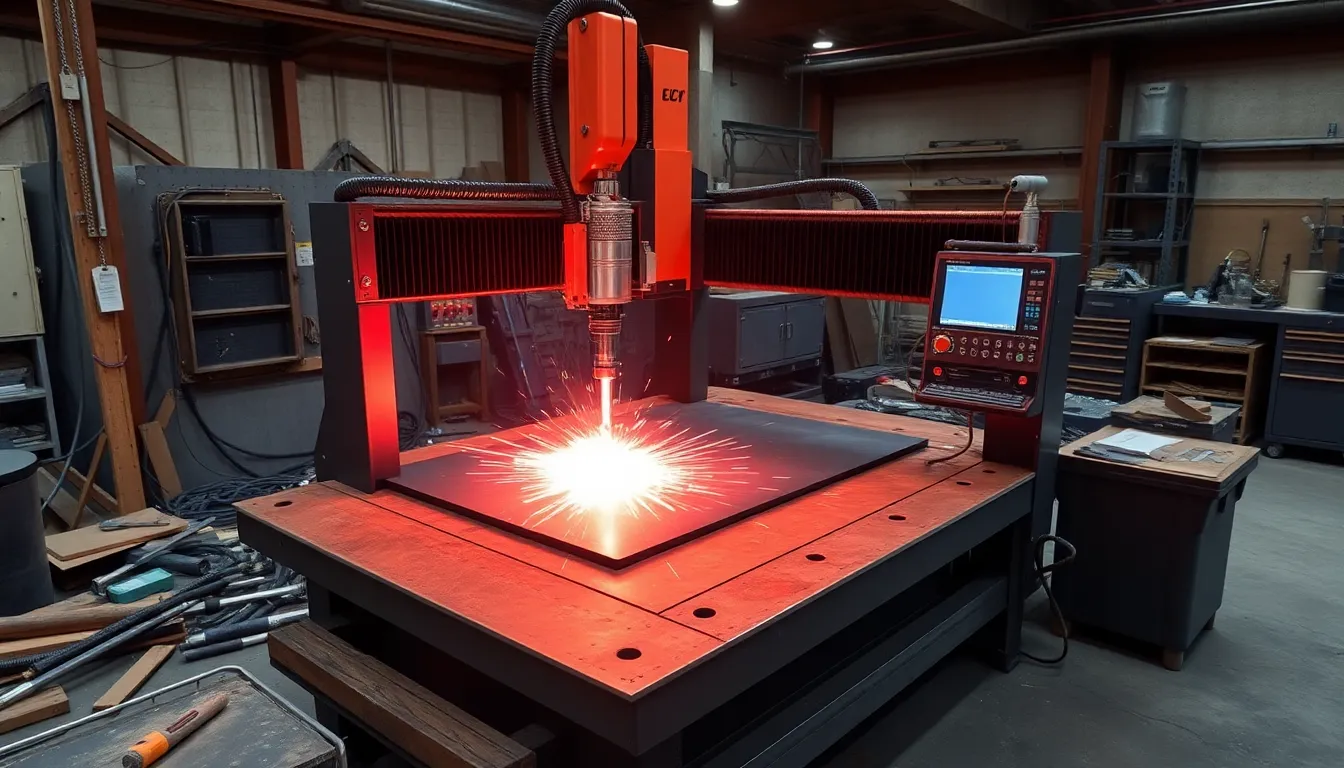

Table CNC Plasma Cutters

Table CNC plasma cutters use stationary worktables combined with computer-guided plasma torches. Operators secure the metal workpiece on the table, and the CNC system controls the torch as it moves along programmed paths. Facilities using table models achieve high precision and uniformity in repetitive parts production. Machine shops and manufacturers apply these cutters for structural steel frames, automotive components, and custom industrial signage. Workpiece sizes accommodate large sheets, and the rigid table offers dimensional stability, crucial for cutting metal up to 2 inches thick. Table CNC plasma systems reach cutting speeds of 500 inches per minute. Yijin Hardware employs table CNC plasma cutters at its Homestead, FL facility for automotive, aerospace, and energy sector components, providing accurate, repeatable results at scale.

Portable CNC Plasma Cutters

Portable CNC plasma cutters offer compact designs that enable transport to remote or on-site job locations. Users operate handheld or wheeled units, oftentimes with built-in, smaller CNC interfaces. These machines fit repair tasks, field fabrication, and maintenance work, making them ideal for construction sites or temporary setups. Typical applications include cutting steel beams, modifying equipment, and on-the-spot fabrication in industries like construction or shipbuilding. While portable models support sheet and plate cutting, they generally handle smaller thicknesses and simpler shapes compared to table models. Yijin Hardware’s fabrication teams utilize portable CNC plasma equipment for quick response projects or customer installations, ensuring metal parts meet required specifications under tight deadlines.

Key Advantages of CNC Plasma Cutting Machines

CNC plasma cutting machines deliver high-speed, computer-controlled metal cutting for sheet and plate materials. They achieve cutting speeds up to 500 inches per minute, reducing labor and production times for jobs such as custom parts and fabrications. CNC guidance ensures precision with highly accurate, repeatable cuts and minimal edge roughness, supporting tight tolerances demanded by manufacturing and fabrication settings.

These machines support cutting for conductive metals—like steel, aluminum, brass, and copper—across different thicknesses. For example, shops use CNC plasma cutters to handle everything from thin sheet metal for signage to 2-inch thick plates for structural frames or machinery components. Full automation minimizes human error, keeping operators away from the plasma arc while open cutting areas enable safer process oversight compared to enclosed laser systems.

Operating and repair costs remain lower than with laser or waterjet machines, with plasma torch replacement usually less expensive. Advanced software integration enables multi-axis control, letting manufacturers meet requirements for parts with complex geometries. Yijin Hardware in Homestead, FL leverages CNC plasma cutters as part of its integrated metalworking services—speeding prototyping and production for automotive, aerospace, and energy clients.

| Advantage | Performance Context |

|---|---|

| Efficiency | Cut speeds up to 500 in/min reduce shop floor time, boost productivity |

| Precision | CNC software provides tolerances for repeatable, high-quality detailed work |

| Versatility | Cuts metals like steel, aluminum, and copper at varied thicknesses |

| Automation/Safety | Reduces operator exposure and error by automating cutting in an open work area |

| Cost Savings | Lower operating and repair costs than laser or waterjet cutting |

Applications Across Industries

CNC plasma cutting machines enable precise, high-speed processing of conductive metals across manufacturing sectors.

- Industrial Manufacturing: Producers cut structural frames, machinery parts, molds, and dies using CNC plasma technology, reducing fabrication time for components such as brackets, panels, and beams.

- Automotive: Companies shape custom steel and aluminum parts for prototypes and vehicle assemblies, matching the industry’s demands for tight tolerances and repeatability.

- Aerospace: Firms process aluminum and titanium for turbine blades, support structures, and airframe components, meeting critical accuracy standards.

- Construction: Crews prepare structural steel, piping, and sheet metal for rapid on-site assembly, streamlining large project workflows.

- Art and Decor: Designers create decorative panels, signage, and detailed metal artwork with complex shapes and smooth edge quality.

Yijin Hardware, based in Homestead, FL, applies CNC plasma cutting for clients in automotive, aerospace, construction, and decorative sectors, integrating the technology into its precision manufacturing workflow for fast part turnaround and consistent results.

Choosing the Right CNC Plasma Cutting Machine

Selecting a CNC plasma cutting machine depends on production needs and metal types. For high-volume manufacturing requiring repetitive, detailed cuts, shops choose large table CNC plasma cutters with multi-axis capabilities. For fieldwork or smaller components, portable units deliver accuracy with easier transport.

Evaluating machine speed impacts project timelines. Table models cut up to 500 inches per minute through 2-inch steel, supporting fabrication for structural frames or machinery parts. Portable systems typically reach lower speeds and cut thinner materials like automotive repair panels.

Prioritizing cut quality ensures parts meet tight tolerances. Advanced systems offer automatic torch height control and software-driven path optimization, reducing edge roughness and material waste. Industries such as aerospace and energy specify these features for complex geometries.

Considering working area size aligns machine footprint with available shop space. Yijin Hardware in Homestead, FL, matches CNC plasma cutting system size to job requirements. For example, Yijin Hardware uses large-format tables for sheet metal parts in industrial assemblies and compact models for custom components.

Assessing support and integration matters for ongoing productivity. Yijin Hardware combines CNC plasma cutting with CNC machining and sheet metal fabrication to deliver complete manufacturing solutions for automotive and medical markets. Gavin Yi, CEO, oversees responsive customer service to ensure parts match specifications.

For more information, contact Yijin Hardware at +1 626 263 5841, email [email protected], or visit www.yijinsolution.com.

About Yijin Hardware

Yijin Hardware, located in Homestead, FL, provides a wide range of precision manufacturing services, including CNC machining, sheet metal fabrication, and custom fasteners.

Led by CEO Gavin Yi, Yijin Hardware also offers additional solutions such as die casting, injection molding, and 3D printing, supporting industries such as automotive, aerospace, medical, and energy. With a commitment to high-quality, precision-engineered products, Yijin Hardware delivers tailored solutions to meet the unique needs of its clients across various sectors.

Contact:

Gavin Yi, CEO

Phone: +1 626 263 5841

Email: [email protected]

Website: www.yijinsolution.com

Location:

760 NW 10th Ave, Homestead, FL 33030

Frequently Asked Questions

What is a CNC plasma cutting machine?

A CNC plasma cutting machine uses computer numerical control to guide a plasma torch, cutting conductive metals like steel or aluminum with high accuracy and speed for a wide range of applications.

How does a CNC plasma cutter work?

It works by following programmed designs, directing a plasma torch with ionized gas to melt and cut metal along the specified path, ensuring clean and repeatable results.

What materials can CNC plasma cutters cut?

CNC plasma cutters can cut any conductive metal, including steel, stainless steel, aluminum, copper, and brass.

What thickness of metal can be cut with CNC plasma machines?

Most machines can cut metals up to 2 inches thick, depending on the model and power output.

What are the main benefits of CNC plasma cutting?

Key benefits include high cutting speed, precision, automation, lower operating costs, and versatility in handling various metals and thicknesses.

Where are CNC plasma cutting machines commonly used?

They are used in industrial manufacturing, automotive, aerospace, construction, signage, art, and custom fabrication sectors.

What’s the difference between table and portable CNC plasma cutters?

Table models are stationary for high-precision, repetitive cutting of large sheets, while portable units are compact, suitable for on-site repairs, and handle smaller, simpler jobs.

Is CNC plasma cutting cost-effective?

Yes, it is generally more cost-effective than laser or waterjet cutting, due to lower equipment and repair costs and faster processing times.

How do I choose the right CNC plasma cutting machine?

Consider your required cutting speed, precision, metal type and thickness, work area size, and level of automation needed for your production.

Why does Yijin Hardware integrate CNC plasma cutting in its services?

Yijin Hardware uses CNC plasma cutting to deliver fast, accurate, and cost-effective metal parts across various industries, ensuring high quality for both prototypes and production runs.